All Attic Protrusions Need CanCoverIt™

UCSD Engineering Capstone Project Conclusion:

“Based on both the summer and winter conditions, the CanCoverIt improves the insulating efficiency of the home. This means that less energy is required to sustain a comfortable household temperature, leading to savings in both electricity costs and greenhouse gas emissions.”

CanCoverIt Is Essential For:

Non-IC & IC Can Light Fixtures

Bathroom Vent Fans

Ceiling Fans

Air exchange Fans

In-Wall & In-Ceiling Speakers

Electrical Junction Boxes

CanCoverIt's Radiant barrier combined with non-conduction mold and fire resistant core stops water, air, sound and energy transfer to optimize overall attic R-Value and U-Value.

CanCoverIt is not just for energy efficiency, but also health, safety & overall building performance. CanCoverIt™ even improves the performance and lifespan of LED lights!

“Purchased a home built in 1961. The original (6) recessed lights in the main room are all made of metal and are not IC-Rated, so there was a fair amount of energy loss. The units are functional and accessible from the attic, but replacing them would require a great deal of effort and money. ‘CanCoverit’ presented the best option for stopping the energy loss and improving the Thermal Barrier in my home. Installed the units about a year ago and I have noticed temperature improvements. Good product and works as advertised. Thanks!”

- Customer Nick

Flexible Airsealing for Attic Fixtures

Data from Johns Manville Research

Built a 24”x24” ceiling section, with a 6” can light in it and ran a series of air leakage tests, at 50 Pa (same as for a blower-door test on a real house)

| Fixture Set Up | Effective Open Area (in") | Leakage @ 50 Pa (cfm) | Reduction in Leakage (%) |

|---|---|---|---|

| IC rated 6" fixture no trim | 2.64 | 33 | |

| IC w/ CanCoverIt Low Profile | 0.95 | 11.8 | 64% |

| IC w/ CanCoverIt Low Profile, sealed | 0.06 | 0.8 | 98% |

| IC w/ CanCoverIt Universal | 1.1 | 13.8 | 58% |

| IC w/ CanCoverIt Universal, sealed | 0.21 | 2.6 | 92% |

| IC w/ CanCoverIt Universal, sealed, vents removed | 1.37 | 17.1 | 48% |

Real World Tested

Study from Dan Ignosci under Comfort Advisors home contractor company:

“We had a blower door available to quantify the measures as they were implemented. The outcomes are listed below:

4534 cfm - Building leakage (leakage) when the attic deck was clean

4387 cfm – Leakage after sealing foam was applied to attic penetrations

3292 cfm - Leakage after CanCoverIts were sealed around 25 recessed light cans

2845 cfm – Leakage after R38 of cellulose was blown onto the attic deck "

CanCoverIt = 27% reduction in airflow

~ 40CFM reduction in leakage per penetration!

Air Sealing & Thermal Conductance Protection

“Before using the product our can lights would drip condensation into the house on very cold winter days when the warm indoor air met the cold attic air at the top of the can lights. I installed the CanCoverIt over a dozen lights, and this winter there was no more condensation dripping. I'm sure we're wasting less heating fuel too. Installation was very easy in the attic; simply unfolding the covers, placing them over the can fixtures and sealing them down using Great Stuff foam.”

- Customer Ben Minshall

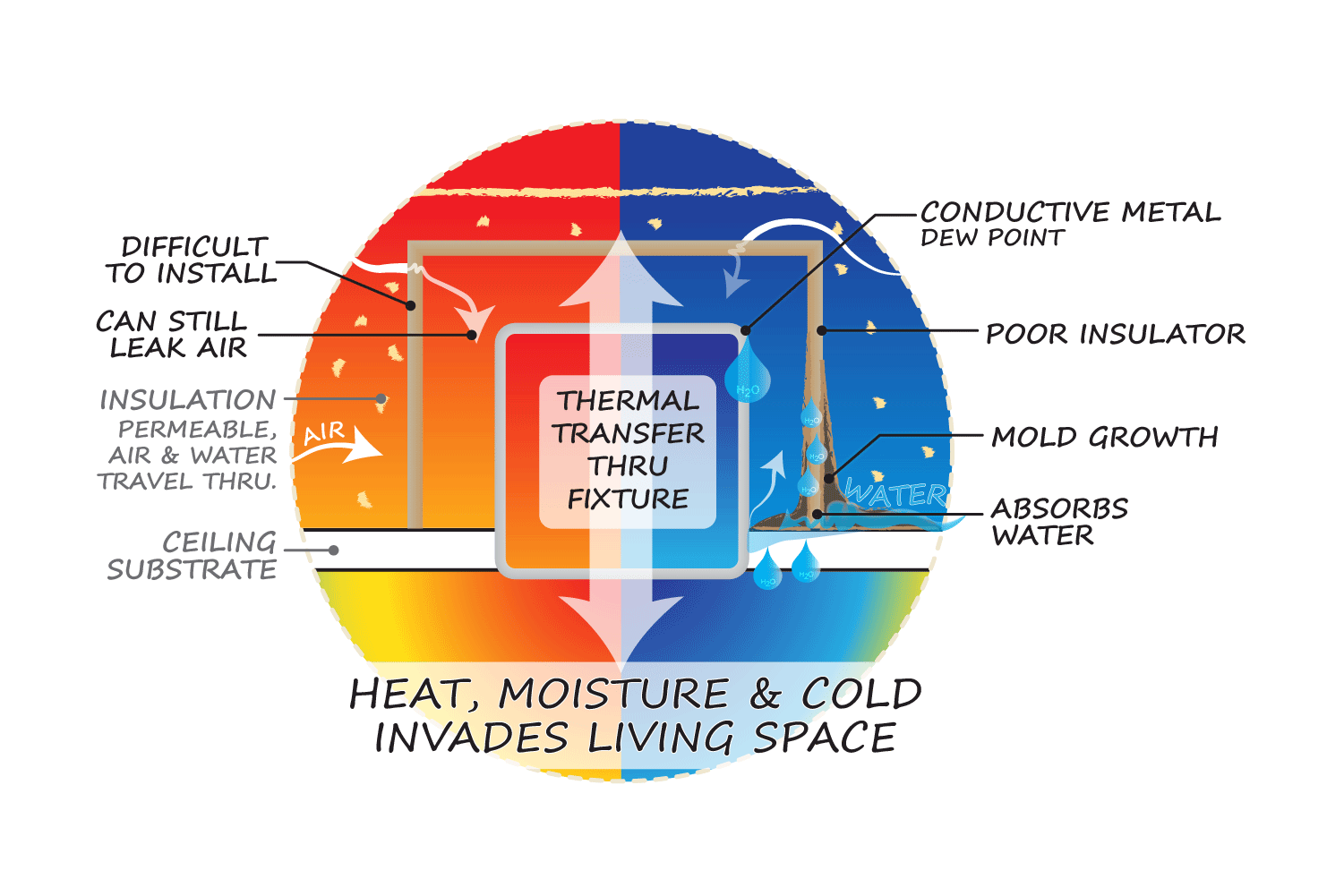

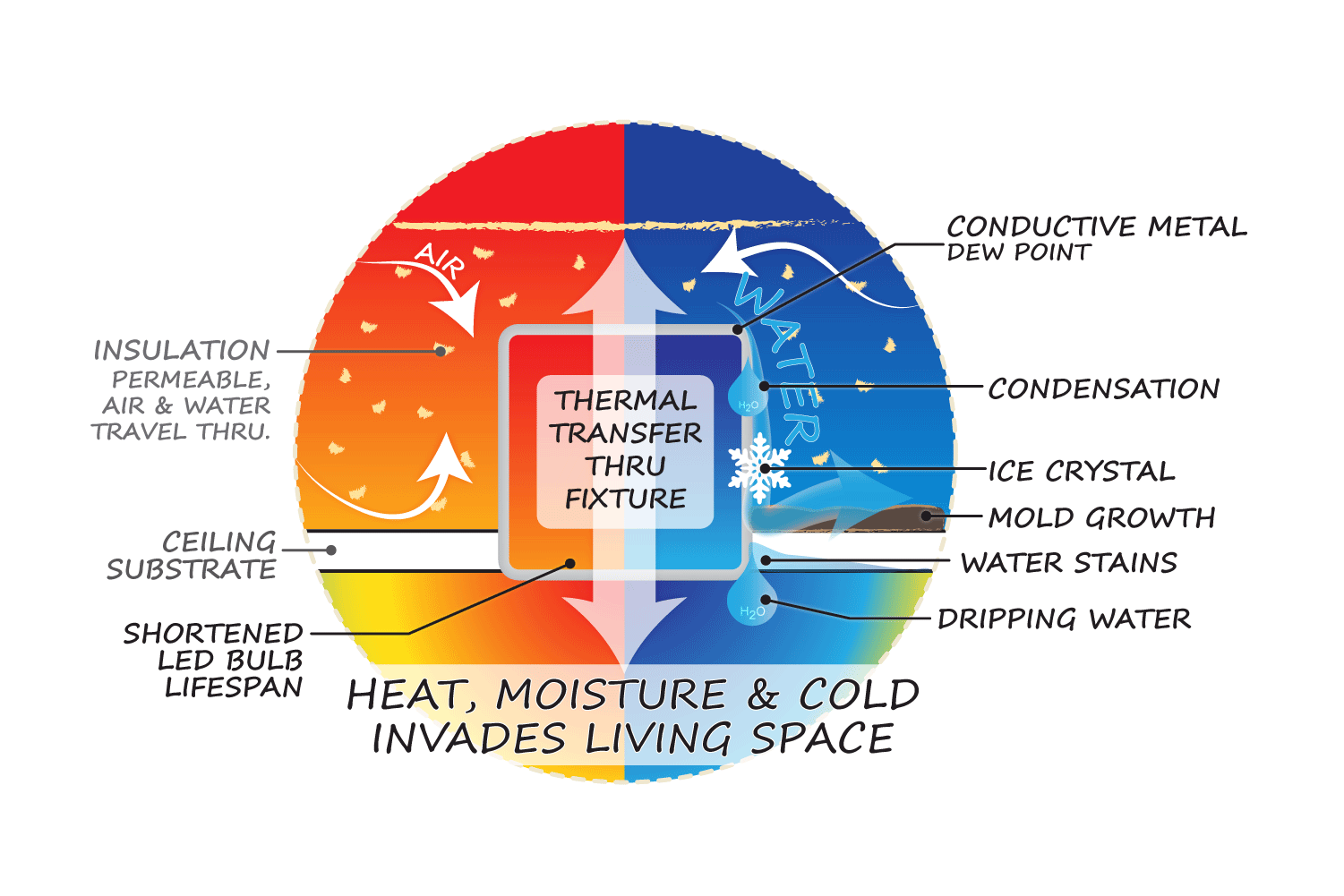

Observed problems caused by metal ceiling penetrations:

Radiant hot and cold spots in the ceiling resulting in extreme energy loss.

A/C and Heater cycling and air drafts.

Moisture and condensation build up leading to mold growth.

Water stains, drips and ice crystals on the ceiling around fixture.

Light bulbs overheating, flickering and shutting off - premature failure.

Left untreated, metal fixtures bleed energy due to extreme conduction and convection energy loss, reducing overall home efficiency.

Attempts such as airtight fixtures, insulation contact fixtures, cardboard/drywall boxes all fail to solve the core problem, and in fact create larger unintended problems!

To solve the core problem every single fixture must be isolated from the attic environment.

CanCoverIt Airtight & Thermal Protected

Air-tight IC-Rated Can-Lights were once considered a solution but in fact they create new even worse problems.

Effectively isolating the fixture requires more than just stopping airflow! Because metal is conductive, attracts condensation and leaks radiant energy.

CanCoverIt™ is the ideal fixture companion.

"CanCoverIt allows the customer freedom to choose whicever lighting fixture they want while still achieving the best airsealing possible." - James Mallory, president Environix, WA

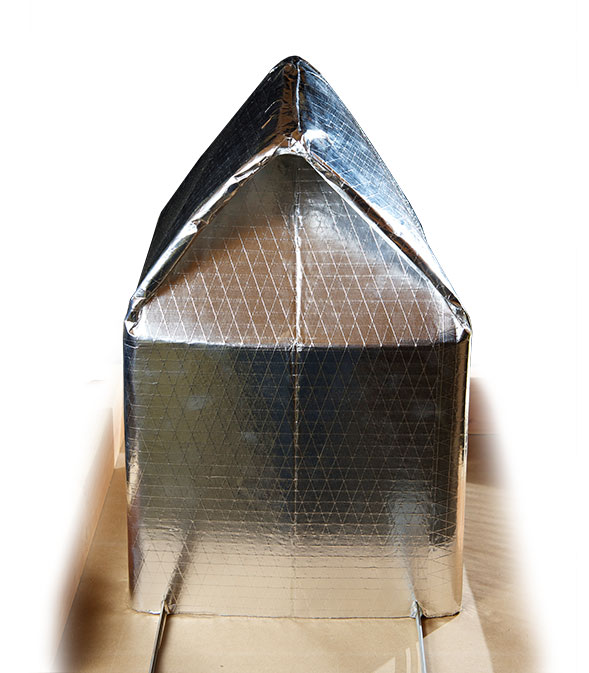

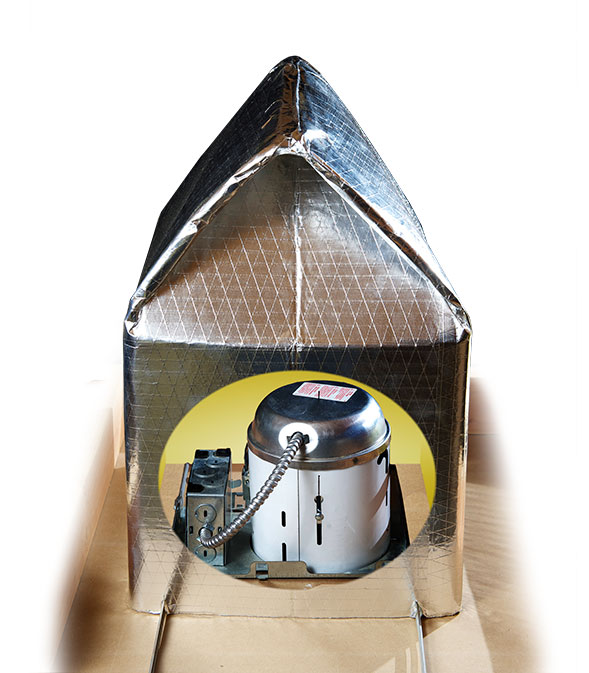

Only CanCoverIt™ has the required geometry, radiant barrier and non-conductive core to effectively isolate the fixture from the attic and bring it safely inside the conditioned interior air.

Optional Venting

With Vents Removed CanCoverIt Still Protects & Offers Safe Operation for Older Non-IC Fixtures.

CanCoverIt Universal Series provides optional safe venting for all fixtures, designed for Non-IC, and creates a dynamic thermal equilibrium chamber to control conduction and convection, greatly enhancing overall home efficiency and comfort.

Even with venting CanCoverIt Universal is still mitigating airflow and stopping thermal transfer.

CanCoverIt Low Profile Series is for IC-rated fixtures and has no vent yet offers a large air chamber inside to protect from overheating. Ideal for modern fixtures with LED lights.

Only CanCoverIt, both series, will provide the correct ambient operating temperature to allow LED bulbs to function best and last longest!

CanCoverIt: Designed For The Real World

Learn more about CanCoverIt from the inventor David Hanacek

CanCoverIt is part of the Net Zero Energy future, available today!

Go hands on with professional installers Comfort Advisors and see why CanCoverIt is the best energy upgrade for your home!

Whole System Approach

Other solutions have proven ineffectual, only CanCoverIt is designed to work with the real world and solve all issues related to metal attic penetrations.

As an example:

A Seattle Washington mold mitigation company used CanCoverIt successfully for fixing can-light related mold problems.

But later they tried switching to LED inserts. Soon after they emailed a large order and said:

“We’ll be back on track for ordering more and more of these. The LED retrofit, just didn’t work as well as [we were] thinking, so we’ve gone back to these on a more regular basis. Have a great day!”

Install CanCoverIt today: save money, increase comfort, and get your home ready for future upgrades!

Testamonials from real people solving real problems with CanCoverIt:

"The covers are easy to work with and we managed to get in and out in a single day with the added blown insulation. A nice safe & snug home and a happy client."

- Dean Alm, Napa Valley Home Inspectors

"Finding CanCoverIt has been amazing for me. It’s been a long time since something has come along that is as good and easy to use as CanCoverIt. Travels well, even comes shipped in a nice heavy box. Cut the product with a knife and scissors. Makes my life so easy and delivers the best results. I don't work without CanCoverIt.”

Rob Calnan, calnansenergy.com, Boston, MA

"Armed with a simply utility knife, it took me about 20 minutes to cover 4 lights... an amazing product and so simple to install that anyone who can properly use a ladder and the business end of a utility knife can do it... especially with the helpful instructional video provided on your website!”

- Chad Sires, Denver, CO (Real Estate Appraiser)

"Thank you for producing CanCoverIt, everyone in our organization loves the product. Our sales team loves it because it shows well to homeowners and helps them sell jobs. Our installers love it because it helps them complete their work faster, and I love it because I now have confidence that my team is using the right product to safely cover can lights in the home."

- Donna, contractor, Virginia Beach, VA

"Before I installed the covers I used a laser temp gun to check the temperature of the light 'buckets' with the light off for a significant amount of time and again after the covers were installed. The temperature dropped around 10º F. The hot air draft in the house has now stopped and the house remains cooler during the day."

- Todd, Midland, TX

"As I prepared to upgrade the efficiency of my home, I wanted to find solutions that would protect the home and be safe for me and my family. After working with my local electrical and fire code officials to find the best product, they both agreed on CanCoverIt. I am happy to have found CanCoverIt, because I sure wasn't looking forward to building boxes out of drywall."

- Michael, owner of a 100-year-old home, Boston, MA

“Love your product, thanks for making a simple affordable project for saving energy any homeowner can do. Now I can afford a great warm tropical vacation.”

- Kris Chernik, Palmer, AK

"No other product addressed my concerns as well as CanCoverIt. All told, I used 21 covers to cover 17 can lights and 4 speakers. It was very easy.”

- Garrick Gallagher, Phoenix, AZ

"The [CanCoverIt™ units] have been working as advertised, we noticed a difference as soon as they were put in, but also did a series of other improvements, radiant barrier in the attic reduced overall attic temp about 10 degree's which helped support the can covers. With both changes the house temperature was cooler and stayed cooler throughout the day."

- Trevor Sim, Hawaii

The Superior Solution

CanCoverIt was designed after extensive research around the operations of can light fixtures, the bulbs that go in them, and the installers tasked with sealing them. As a result CanCoverIt is the ultimate solution to one of the home efficiency field's most pressing and difficult problems.

CanCoverIt controls fluctuations in temperature and ensures safe heat transfer with no excess waste.

CanCoverIt is the first practical, safe, cost effective, efficient solution for insulating non-IC can light fixtures providing complete residential solutions for both contractors and DIYers. CanCoverIt fills an overwhelming need for a safe economically viable and uniform insulating solution.

CanCoverIt's performance advantages include:

Ships and stores flat.

Pop open and go, no assembly required.

Safe and durable to install and can be left in the attic for years.

An air-tight fit once sealed to the attic floor.

Easy to cut and fit around brackets wires, and framing.

Our Universal Series features passive venting technology allows all recessed light fixtures to be insulated, even Non-IC rated fixtures.

The Low Profile Series is an excellent option for IC-rated can light fixtures.

Without CanCoverIt not even air-sealing can help: thermal transfer runs wild!

CanCoverIt provides comfort in all weaher conditions. Save money, increase comfort.

| Fixtures Without CanCoverIt™ | Fixtures With CanCoverIt™ |

|---|---|

| Air leaks causing uncomfortable drafts, inconsistent room temperature and wasted energy | Eliminates drafts - Stops air leakage |

| Extreme attic temperature radiates through fixtures | Eliminates thermal energy transfer |

| Light bulbs overheat, flicker, shut off and fail | Light bulb heat safely and effectively diffuses within the CanCoverIt™ conditioned air space |

| LED bulb premature failure due to temperature changes | Provides consistent operating environment to maximize LED bulb life |

| Dew-point - moisture condenses causing ice crystals, water stains, dripping water and mold growth | Eliminates moisture buildup risk |

| Acoustic problems - Sound transfers through fixtures especially when located under hard surface floors | Air volume around fixture & insulation controls sound transfer |

| Compromises overall attic R-value, regardless of insulation thickness | Optimizes attic R-value, allows insulation to work effectively |

| Constant A/C and heater cycling depending on season | Reduces heating/cooling system cycles by over half |

Retrofit the Future: The 20 minute crash course in fixtures and the retrofit opportunity.

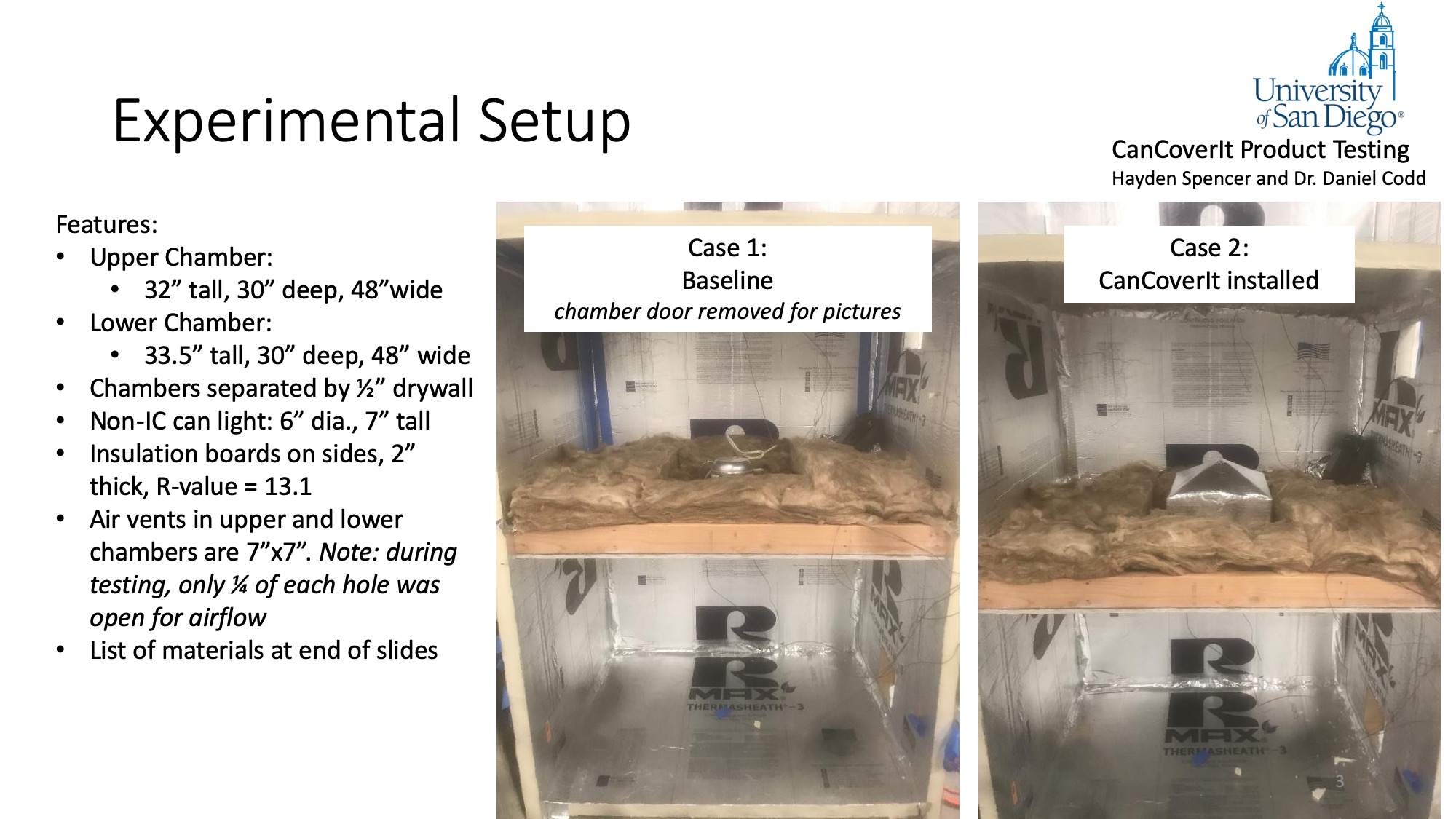

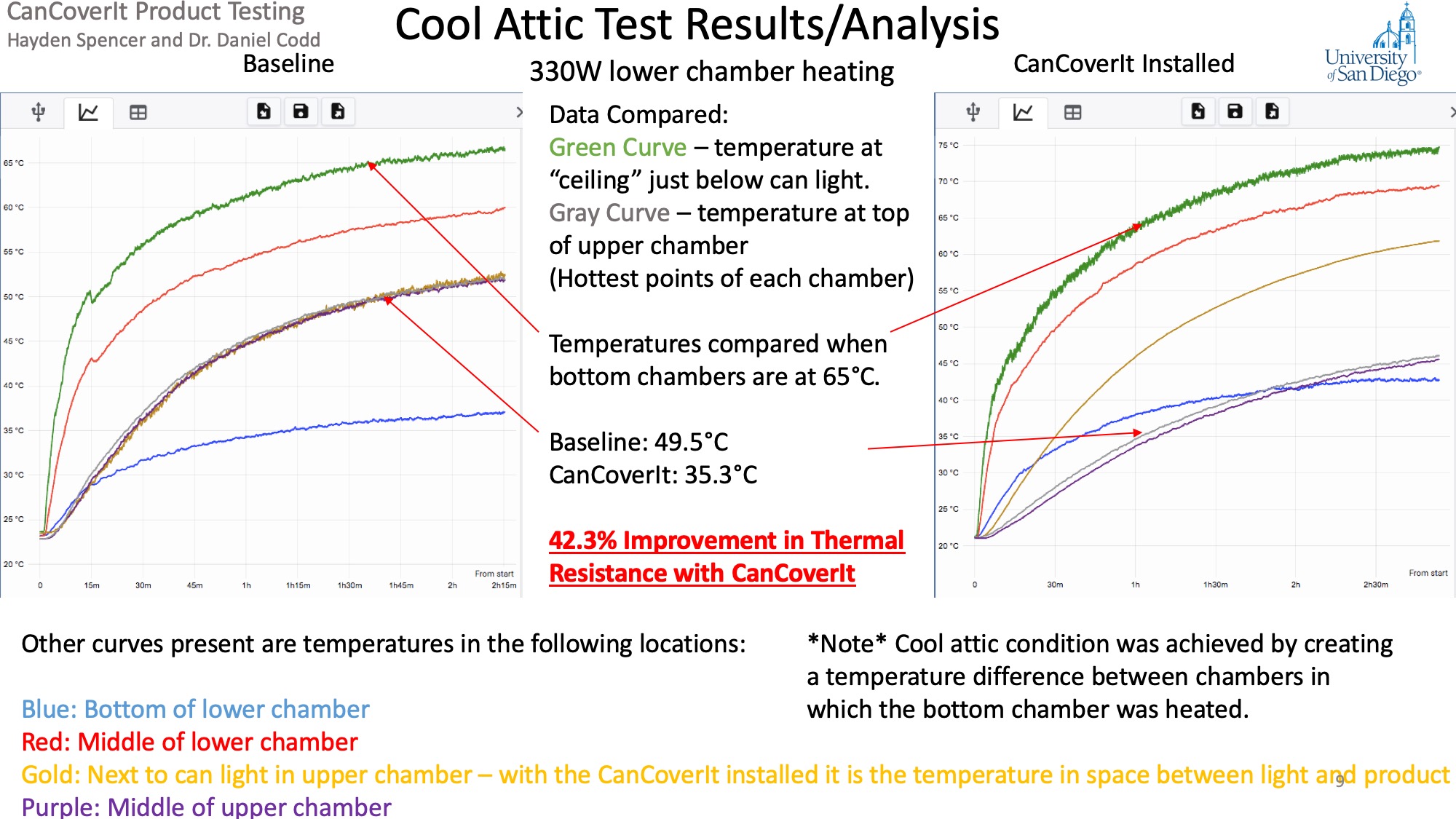

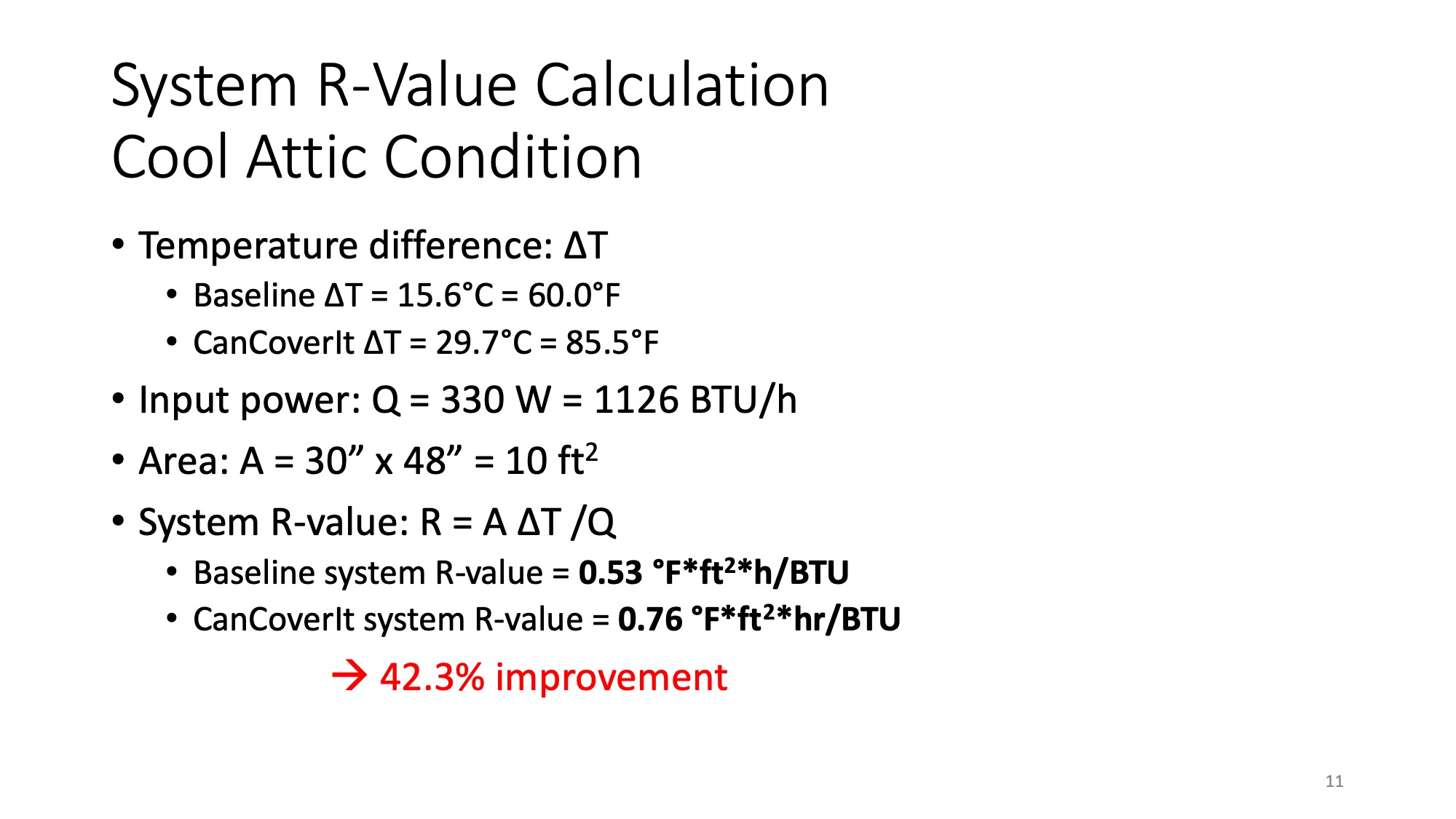

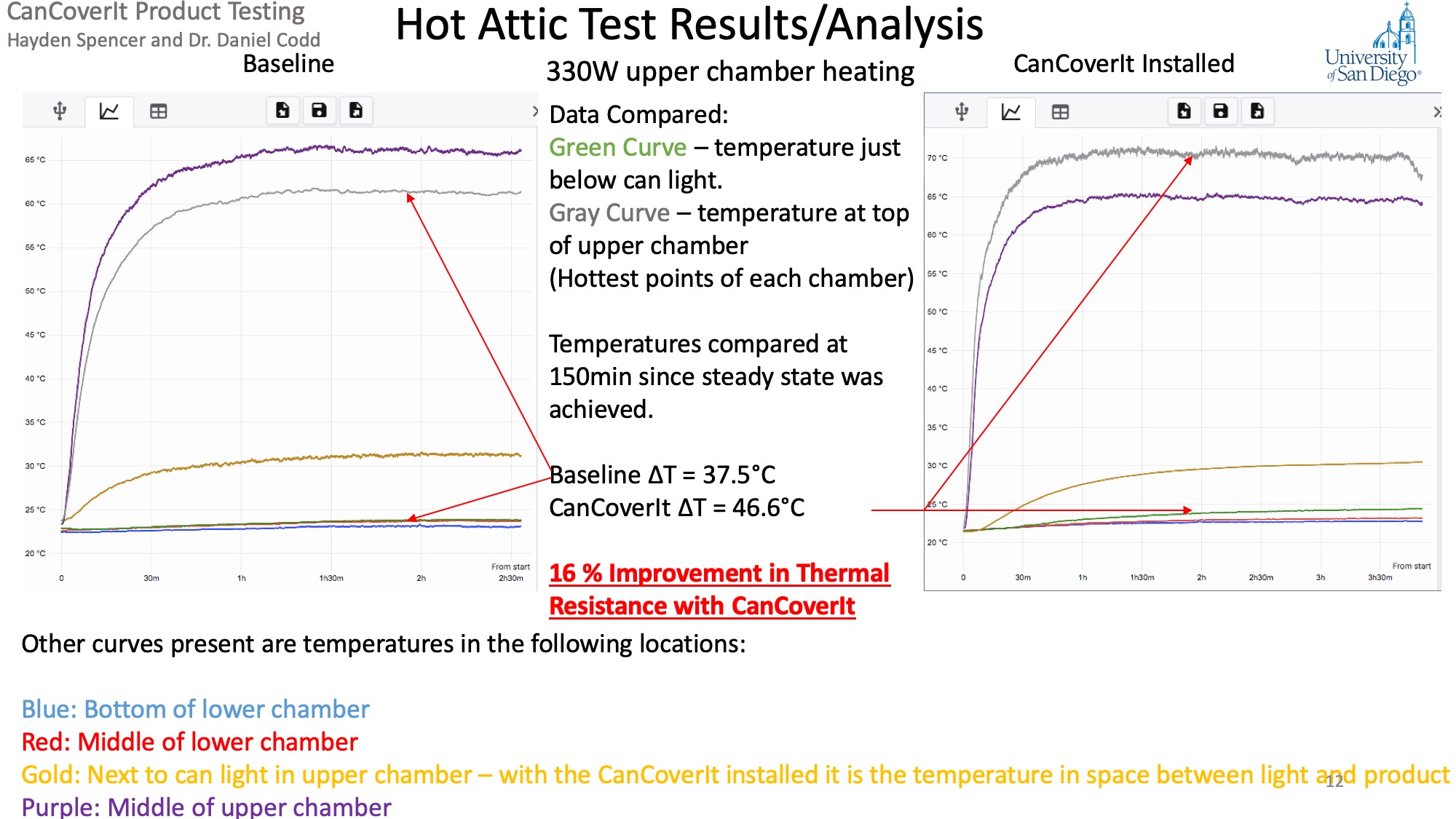

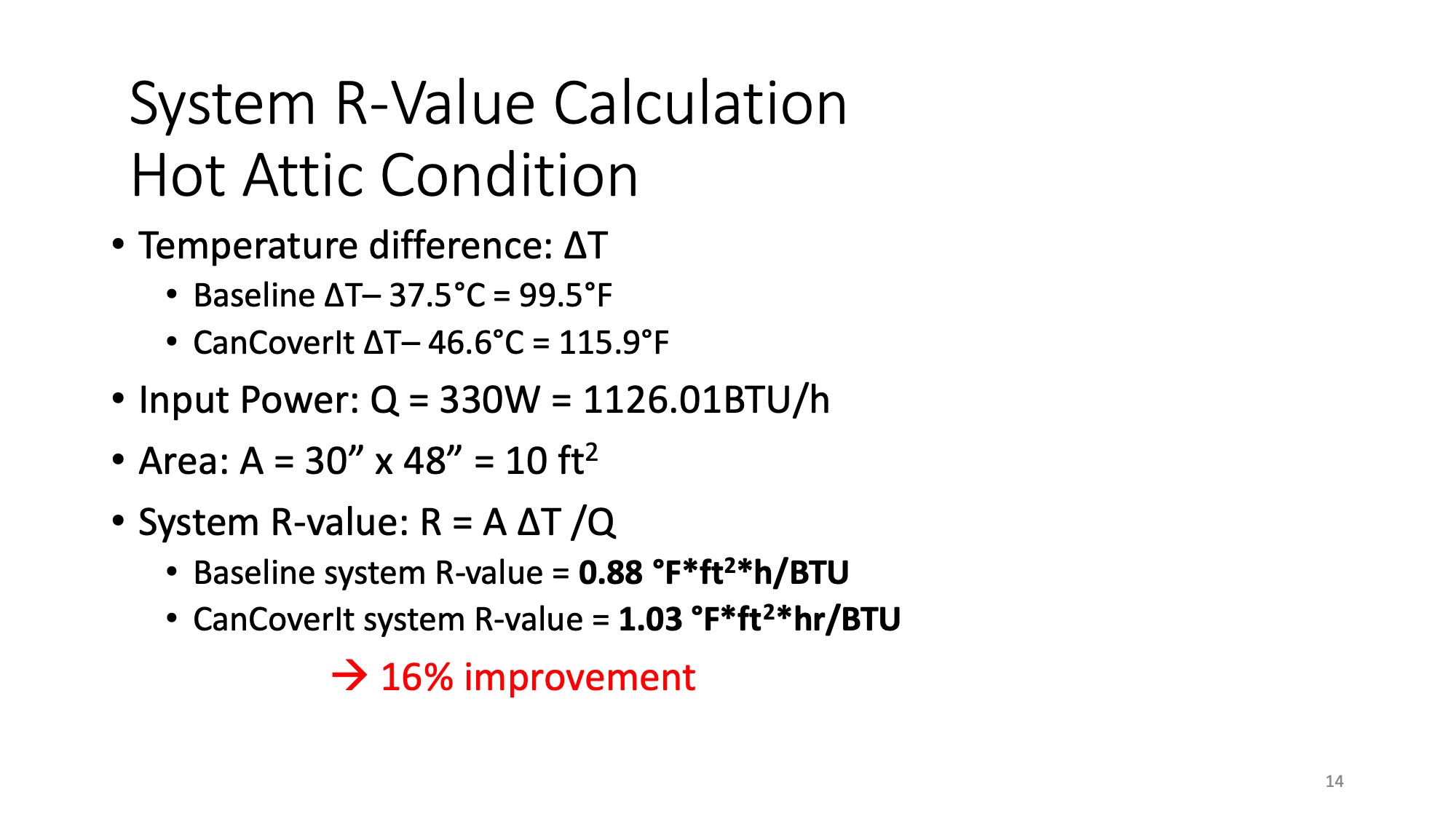

Through CanCoverIt’s involvement in the Southern California Regional Energy Innovation Network (SCEIN) we have sponsored two student teams to study the benefits of CanCoverIt protection for metal attic fixtures.

In a SCEIN first, CanCoverIt orchestrated University of San Diego (USD) and University of California San Diego (UCSD) into one study consisting of two parallel operations.